How Thick Should a Concrete Driveway Be? Proper Guides For Building a Driveway

The thickness of a concrete path depends entirely on its intensity. There’s no question that a thick concrete entrance or driveway substitute is an excellent investment for your home or company.

A concrete road must be stable to allow the driving of cars and trucks. It will boost your look and make it safe for your children to ride scooters, minimize erosion and make it easier to keep your car clean.

However, there arises a large query about how deep the concrete should be? Usually, concrete drive panels are 4 to 6 inches thick for extra support.

This thickness will increase your concrete costs by around 20%. But it will also increase the carrying capacity of your driveway by almost 50%. Of course, the thickness of the concrete depends on the driveway’s soil.

Let’s not waste any more time discussing the matter here. We will be elaborating the facts you need to understand to make your driveaway thick.

Let’s get started;

Factors To Determine Thickness Of Concrete Driveway

Concrete is a common flooring material. The explanation is a great function, which makes it ideal for all exterior environments. However, determining the correct thickness of the concrete driveway will go long. Their role, longevity, and even existence can be decided.

The thickness of the concrete layer depends on your driveway use. Commercial highways must also resist heavy vehicles, but residential drives must usually combat only one or two passenger vehicles.

Here are key factors that play an essential role in determining the correct thickness.

Type of base

On the soil, you want to build your concrete driveway, which is a significant factor to consider. In some areas, the type of soil differs from various regions. Dirt, Concrete Paving Contractor often goes for a structural base of 3-6 inches before concrete on with expansive concrete pouring.

You’ll need a firm, stable base to support the weight of your concrete. If the base soil is sandy and loose, you can add clay to firm it up. If the soil is too loamy, add sand or gravel to make it level. Whether you add material or not, you should compact the ground to make it firm and even.

Purpose of the driveway

Contractors prefer a standard thickness of 4 to 6 inches for concrete paving with light circulation. However, this varies concerning the floor with a regular route for waste trucks, delivery trucks or other heavy trucks. The concrete pavement requires extra strength and longevity in this situation.

Although this is a significant factor, experts suggest that you stop driving and parking heavy vehicles in your driveway.

Budget

Adding one or two additional inches can be sufficient to increase the structural integrity of the pavement. This maximises the pavement’s strength by 50%.

On the other hand, the other concrete would increase the budget by 20% of the total project cost. Therefore, it is curious to remember that you need a thicker and stronger entrance.

Of course, only the concrete thickness of the driveway will matter in the long run. A small increase in your budget would, therefore ultimately prove profitable.

Building a driveway

Building one can be labour-intensive and costly. But for folks that aren’t afraid to tackle big jobs, building your driveway can be a rewarding project. Let’s get to know the steps.

Estimate concrete amount

For this calculation, you will have to convert your measurements to feet. Multiply the length of your driveway by width to determine how many cubic meters of concrete you will need.

It is then multiplied by .35, four inches (10 cm) in terms of the feet. Take the final figure and divide it by 27 cubic feet in a cubic yard.

You may want to increase your order by approximately 10% to allow spillage and error.

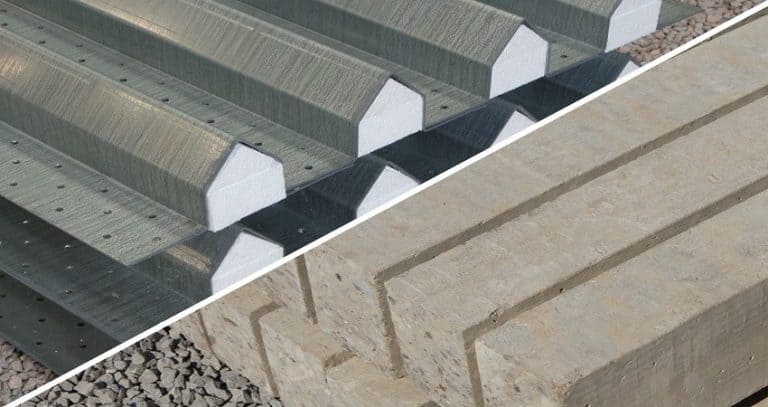

Forms and reinforcement materials

It is necessary to build wood to strengthen your forms and stakes, all of which must be considered in your budget. Pine board measuring 1 inch by 4 inches is usually enough to lay an entrance and several stakes of four inches.

The refurbishing materials you want in your concrete must also be selected. The best choice for this is iron rods.

Layout the shape

Position your form by driving small stakes of wood or metal where the drive goes down the street, then at the top of the driveway and then attaching the builder’s line to them to visualise the drive path. Verify often that your layout is in line with the entrance plan you have developed.

Masonite or plate wood is strong enough but flexible enough to support the concrete load. When you are done, you can assemble and disassemble your forms with the screws and a power drill. Place all 3 feet or so on your stakes to ensure the shape is in place.

Make a thick base

Driveways generally have a thickness of at least 4 centimetres. Thicker concrete is recommended for heavier vehicles. A straight or string across the top of your forms is done. Grading is done by tying.

If you find areas that are not even with the rest, add material or remove it to ensure even grade. In places that are not as high as the others, add gravel or crushed rock.

Reinforcing

The addition of a steel reinforcement increases your entryway strength and is strongly advisable. Steel helps to support the concrete and distributes the weight of your car.

The rebar or heavy-duty mesh ensures that the concrete remains intact structurally. Polypropylene fibre refurbishment must also be added to the concrete mix at the concrete plant.

Pour concrete

Sprinkle with the concrete relatively fast, and the concrete wheelbarrowing the length of a significant path is work-intensive. If your trucks cannot get in a position to add their payload into the forms directly, consider hiring a pumping contractor for concrete materials.

You can also rent a front bucket piece of equipment, such as a steering steer, a tractor or a wheelbase motor to facilitate work.

Texture to the concrete

Particularly in wet conditions, perfectly smooth concrete can make traction risky for your truck. Drag a broom or bag along the cement, as its drying process allows your tires to grip a textured surface. This must be done as long as the concrete is still sufficiently damp for the texture.

Curing

Consider watering the concrete for a few days to moisturise it. For at least 3-7 days, you should protect your concrete drive against extreme weather. Don’t park your car until it cured on the driveway.

Some Important FAQs

This section has arranged many questions and answers, which may help you understand the above discussion.

- Can you pour a driveway with bagged concrete?

You can mix and quickly pour the whole plate with a large enough cement mixer. The process of making an entrance with Quikrete is the same as any other concrete. You just mix and pour the Quikrete in at the halfway point after you have created the foundation hole and laid a rebar grid.

- Do you need stone under concrete?

Because the concrete is a highly porous material, any moisture it contains is absorbed. This may lead to pooling. The water will flow and erode your slab without crushed stone. A layer of crushed stone adds good drainage and creates a barrier from the ground to your dome.

- Can you pour concrete over existing concrete?

Yes, you can cover an existing slab with a concrete pad. The overlay on the existing structure needs to take into account the additional height and weight. Polymers, portland cement or epoxy surfaces may be part of overlays.

- Can I pour concrete directly on dirt?

Yes, you can pour concrete over dirt.

Final Words

In this article, we have tried to maintain the workflow, which can be done by yourself. You want to make a driveway in front of your house you should do it by yourself. It will both save money and time.

But as we always recommend, you have the liberty to call in an expert to help you out with the task.

We hope this article will be useful to you. Good Luck.

I’m a concrete contractor by trade and have been working in the industry for over 25 years now. I’ve seen (and done) it all when it comes to concrete, and I love sharing my knowledge and experiences with others who are interested in learning more about this amazing material. In my spare time, I enjoy spending time with my family, fishing, and watching NASCAR races.

My aunt wants to connect her outdoor space to her main home area, but she’s unsure how. I like your suggestion of hiring a concrete contractor since they know how thick a concrete driveway should be before working on it. I’ll be sure to pitch this idea to her so that she could try it out.